Athos-55 / 65 / 80 / 110

Specially developed for sheet-fed packaging industry, such as, pharmaceutical, tobacco, 3C electronic, cosmetic, food, Tag, Card, liquid packaging etc. It’s versatile function allows accurate inspection of highly-reflective substrates as well as normal ones, for instance gold and silver metalized film paperboard, laser film paperboard, aluminized material and stamping material.It is able to inspect defects like missing print, dirty spot, ink splash, registration, color deviation, streak as well as embossing defects and variable data.

Features

Specifications

|

Mode |

Athos-55 |

Athos-65 |

Athos-80 |

Athos-110 |

|

Application |

Color Box |

|||

|

Inspect Defects |

Ink Spot, Missing print, Dirty Spot, Color variation, Hot Foil, Embossing disposition, Die Cutting, Pressure Mark, Varnish, Laminating, Bar Code |

|||

|

Max. Inspection Size(L X W) |

550 X 420 mm |

650 X 500 mm |

800 X 600 mm |

100 X 700 mm |

|

Min. Inspection Size(L X W) |

100 X 100 mm |

|||

|

Sheet Weight |

90-350 g / sm |

|||

|

Max. Inspection Speed |

250 m/min |

|||

|

Min. Spot Defect Accuracy |

0.1 mm² |

|||

|

Min. Line Defect Accuracy(L X W) |

0.1 X 5 mm |

|||

|

Print Registration Accuracy |

±0.15 mm |

|||

|

Color Deviation Accuracy |

ΔE≥3Nbs |

|||

|

Feeding Method |

Bottom Feeding|Scratch less Feeding|Top Feeding |

|||

|

Delivery Method |

Stream Method|Stacking Method |

|||

|

Ejecting Method |

Air Knife|Reverse Turning |

|||

|

Inspection Control Box Size(L X W X H) |

700 X 700 X 1200 mm |

|||

|

Machine Electric Box Size(L X W X H) |

1300 X 420 X 1400 mm |

|||

|

Power Supply |

380V / 50HZ / AC3 |

|||

|

Air Supply Capacity |

10Bar |

|||

|

Machine Weight |

4500Kg |

4500Kg |

4800Kg |

5200Kg |

|

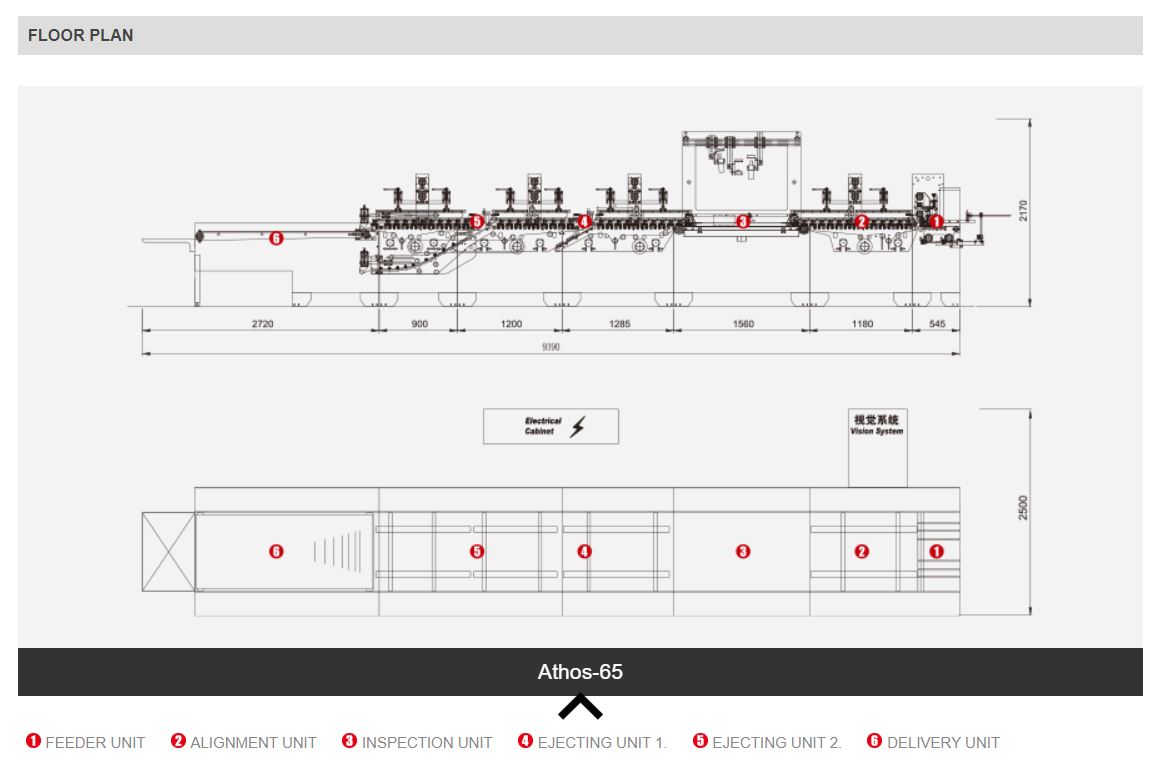

Machine Dimension(L X W X H) |

9390 X 2500 X 2170 mm |

9390 X 2500 X 2170 mm |

9390 X 2700 X 2170 mm |

9390 X 3000 X 2170 mm |

|

Power Requirement |

21KW |

21KW |

21KW |

25KW |

PRODUCT BROCHURE

PRODUCT BROCHURE