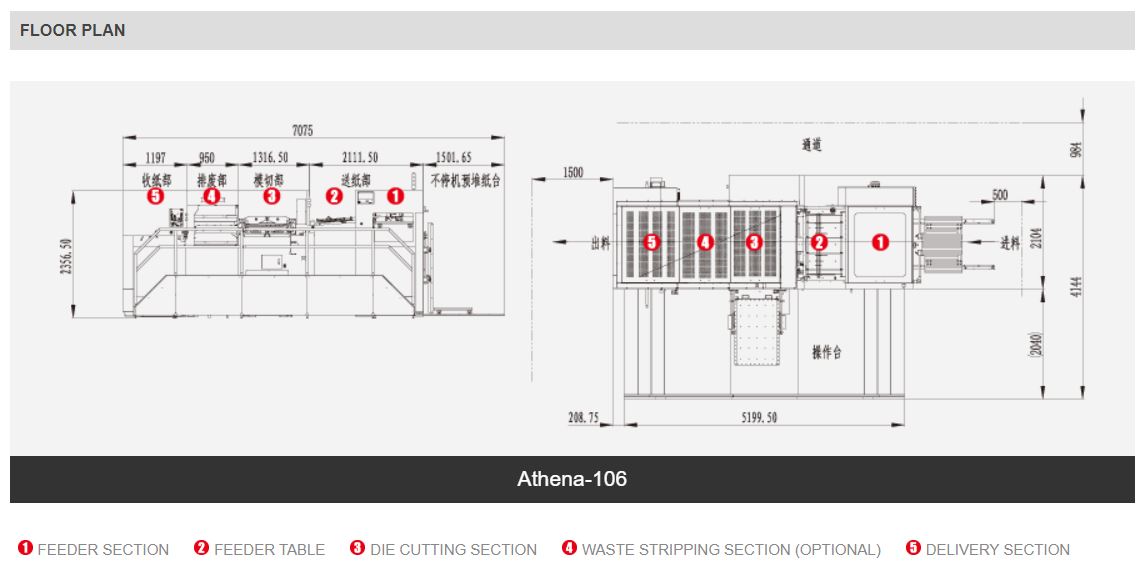

Athena-106

Guangzhou SimSun Machinery Co., Ltd. is located in Nansha District, Guangzhou City, China. It’s a leading supplier for post-print machinery with professional technology to produce and offer high quality machines, involving machinery such as Folding and Gluing Machine, Die Cutting Machine, UV Spot Coating Machine, Film Laminating Machine and so on.Guangzhou SimSun Machinery Co., Ltd. is located in Nansha District, Guangzhou City, China. It’s a leading supplier for post-print machinery with professional technology to produce and offer high quality machines, involving machinery such as Folding and Gluing Machine, Die Cutting Machine, UV Spot Coating Machine, Film Laminating Machine and so on.

Features

Specifications

| Model / Specifications | Athena-106 |

| Max. sheet size (L x W) | 750 x 1060 mm |

| Min. sheet size (L x W) | 350 x 400 mm |

| Sheet Thickness | 90 – 1800 g / sm cardboard,corrugated board≤4mm |

| Max. Machine Speed | 7500 Sheet / hour |

| Max. Die Cutting Size (L x W) | 720 x 1040 mm |

| Chase Inner Size (L x W) | 745 x 1080 mm |

| Steel Plate Size (L x W) | 736 x 1080 mm |

| Min. Gripper Margin | 8 mm |

| Max. Cutting Pressure | 300 tons |

| Power Required | 20 kw (CS) / 19 kw (C) |

|

Machine Dimension (L x W x H) |

7075 x 4144 x 2356 mm (CS) / 6125 x 4144 x 2356 mm (C) |

| Machine Weight | 15.5 tons (CS) / 14 tons (C) |

PRODUCT BROCHURE

PRODUCT BROCHURE